Learn about the details and benefits of the chrome plating process on metal rollers

Description:

Discover how to select suitable CNC machining tools through this comprehensive guide. Explore key considerations for choosing CNC machining tools, different tool types, and expert advice to ensure accuracy and efficiency in the machining process.

Introduction

Choosing the right tools is crucial for achieving accurate and efficient results in CNC machining. “How to choose CNC machining tools” is a common question among professionals and enthusiasts in the field. This guide aims to provide a comprehensive overview of key considerations, tool types, and expert tips to assist you in making informed decisions and optimizing your machining process.

When selecting CNC machining tools, several key factors should be considered. Let’s explore each of these factors for better understanding.

Material Compatibility

Different materials require specific tooling solutions for optimal performance. The first step in choosing CNC tools is identifying the materials you will be working on. Whether it’s metal, plastic, or composites, each material demands a specific tool type to achieve desired results. Consider the hardness, density, and characteristics of the material to determine suitable tooling options.

Machining Operation

The type of machining operation you intend to perform is another critical factor. Whether it’s milling, turning, drilling, or grinding, each operation has unique tooling requirements. Understanding the nature of your machining task will help select a tool that matches the demands of that specific operation.

The geometry of the tool plays a significant role in the machining process. Factors like rake angle, helix angle, and cutting edge geometry can greatly impact tool performance. Analyze the tool geometry options available and select one that aligns with your machining needs for optimal chip evacuation, surface finish, and tool life.

Cutting Speed and Feed Rate

Determining appropriate cutting speed and feed rate is crucial for achieving accurate and efficient machining. These parameters depend on various factors like material, tooling, and machine capabilities. Refer to manufacturer’s recommendations and consider your project’s specific requirements to establish ideal cutting conditions.

Tool coatings and materials can significantly enhance CNC tool performance and durability. Consider coatings like TiN, TiCN, TiAlN that provide benefits such as improved lubricity, heat resistance, wear resistance. Similarly, choose tool materials like carbide, high-speed steel (HSS), or ceramics based on specific machining needs and material compatibility.

Rigidity and Stability

Maintaining rigidity and stability during machining is vital for precision and minimizing vibrations. The tool holder, spindle, and machine setup contribute to overall system rigidity. Ensure proper clamping, alignment, and stability of tools and components to prevent issues like tool deflection and poor surface finish.

Cost Effectiveness

Cost-effectiveness is a major consideration when selecting CNC machining tools. While quality tools may have a higher price tag, they often deliver superior performance and longevity. Assess the balance between cost and capabilities to make an informed decision aligned with your budget and long-term goals.

Tool Life and Maintenance

Tool life and maintenance directly impact the overall productivity and cost-efficiency of the machining process. Evaluate the life expectancy and maintenance needs of the tools under consideration. Opt for tools that offer extended life, easy maintenance, and possibilities of reconditioning or regrinding to maximize utility and minimize downtime.

Now that we have explored key considerations, let’s delve into the different types of CNC machining tools available in the market. Each tool type has its unique characteristics and applications.

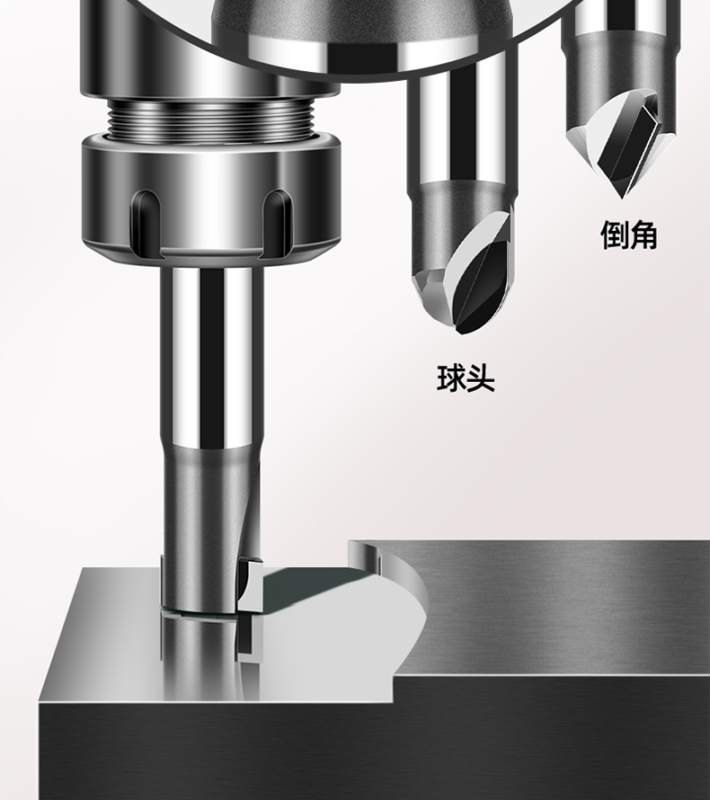

1.End Mills

End mills are versatile cutting tools used in milling operations. They feature a cylindrical shape with cutting edges on the periphery and end face. End mills come in various designs like square end, ball nose, corner radius to suit different milling needs and material types.

End Mills

End Mills2.Drills

Drills are primarily used for creating holes in workpieces. They come in different configurations like twist drills, center drills, spotting drills. The choice depends on factors like hole diameter, depth, material, and accuracy needs.

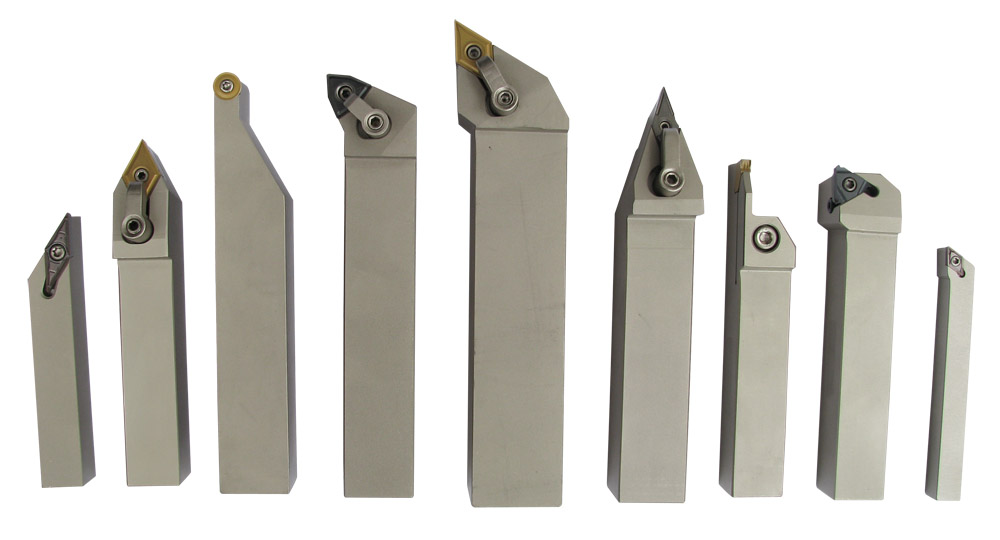

Turning tools are used in lathe operations for cylindrical or conical shaping of workpieces. They typically consist of replaceable inserts mounted on a tool holder. Turning tools are available in different types, including external turning, internal turning, threading and grooving.

Boring tools are used to accurately enlarge existing holes. They provide greater accuracy and surface finish compared to drills. Boring bars, boring heads and indexable boring tools are some common types.

5.Taps

Taps are essential for creating internal threads in holes. They come in designs like hand taps, machine taps, spiral point, and spiral flute taps. Choosing the right tap depends on factors like thread size, pitch, material, depth needs.

6.Inserts

Inserts are replaceable cutting tips used in various CNC machining operations. They are commonly used in turning, milling, drilling. Inserts come in different shapes, sizes, cutting materials to suit specific machining requirements.

7.Chamfer Tools

Chamfer tools are designed to chamfer edges and corners of workpieces. Their main purpose is to break sharp edges and form beveled surfaces for enhanced appearance, safety, and functionality of parts.

Chamfer tools usually have different designs and shapes to suit varying chamfer requirements. Common types include V-point chamfer tools, flat bottom chamfer tools, and ball nose chamfer tools.

Knurling tools are used to produce patterns or textures on the workpiece surface. They form various knurl patterns like straight, diamond, spiral by rolling over the surface. Knurling tools typically consist of multiple cutting teeth to accomplish multiple cuts in one pass, improving efficiency.

9.Reamers

Reamers are tools designed to produce reamed holes or slots in workpieces. They cut specific hole profiles through rotating and feeding motion for fitting other components. Reamers often have multiple cutting edges for simultaneous cutting on the workpiece, increasing efficiency. Reamer design and size vary based on different hole requirements.

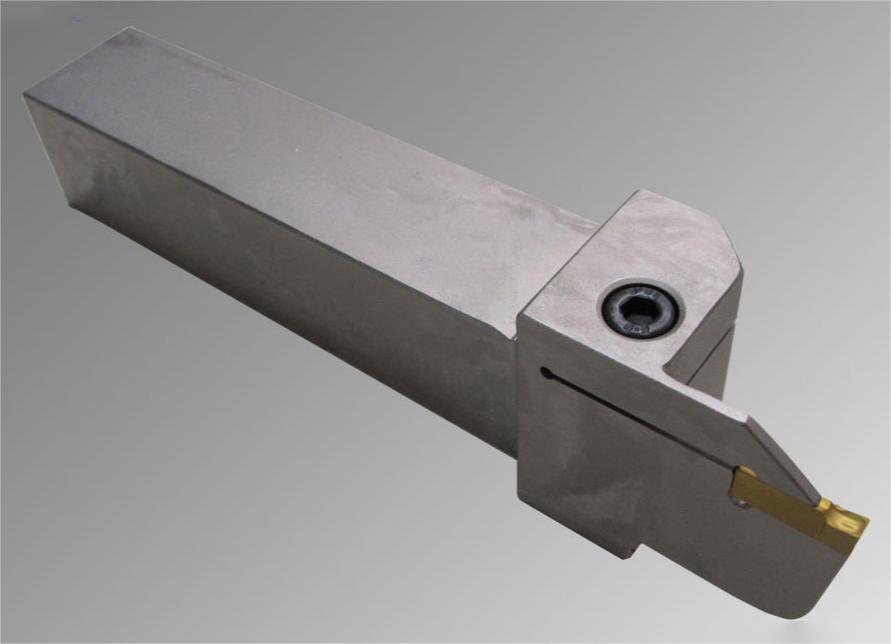

10.Slotting Tools

Slotting tools are designed to produce slots or grooves in workpieces. They make specific slot profiles through rotating and feeding on the work surface to accommodate other parts or fulfill particular machining tasks. Slotting tools often have multiple cutters for simultaneous cuts, improving efficiency. Their design and size depend on varying slot requirements.

11.Deburring Tools

Deburring tools are designed to remove burrs and protrusions on component surfaces that may result from the machining process. These burrs can deteriorate part quality and finish. Deburring tools feature special cutting edges that lightly scrape off burrs without damaging the original workpiece dimension or shape. The edges are often sharp with a slight helix angle for minimal cutting and damage during use.

Cutting tools are designed to cut or sever the workpiece into desired shapes and sizes. They are typically used for straight cutting or parting operations on components to meet dimensional or profile requirements. Cutting tools usually have sturdy cutting edges to exert high cutting forces on the work metal, plastic, wood or other materials. The edges can be straight or serrated depending on the demands of the cutting application.

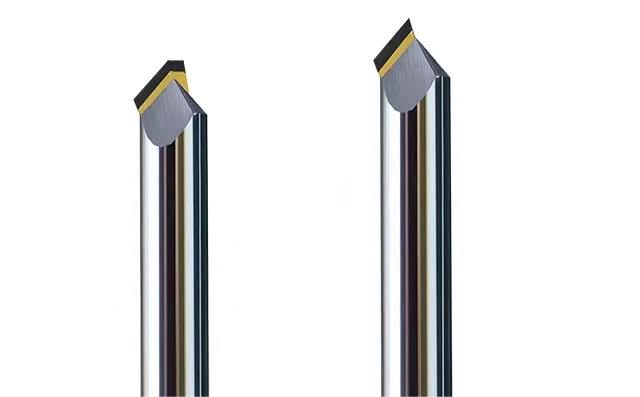

Diamond tool cutting edges typically consist of diamond grains brazed onto the tool insert. The grains are fixed using metal alloys or other composites, forming a sturdy cutting edge. Owing to the hardness and thermal stability of diamonds, these tools resist wear and endure prolonged cutting operations.

Mirror cutting tools are designed to generate high-gloss mirror finishes on surfaces. For certain workpieces, high-gloss polished finishes are required for appearance and functionality. Mirror cutting tools play a critical role in achieving this machining effect. They feature specialized cutting edges and tool geometry to make micro-fine cuts on the surface for excellent flatness and smoothness, typically on hard metals like stainless steel and aluminum alloys.

- High Speed Steel (HSS):

HSS is a common CNC tool material offering good wear resistance and thermal stability. It is suitable for machining low to medium strength materials like iron, aluminum alloys, plastics.

Carbide tools have excellent hardness and wear resistance, suitable for machining high hardness and strength materials like stainless steel, alloy steels, titanium alloys.

- Cubic Boron Nitride (CBN):

CBN tools are superhard tools suitable for hardened steels, high speed steels, and powdered metal alloys.

- Polycrystalline Diamond (PCD):

PCD tools are superhard tools for non-metallic materials like aluminum, copper, carbon fiber, ceramics.

Diamond tools have diamond grains as the cutting edge, suitable for high hardness and brittle materials like glass, ceramics, gemstones.

Coated tools have a coating deposited on the tool substrate using CVD, PVD, etc. Common coatings include titanium nitride, titanium carbide, aluminum nitride to enhance tool life and performance.

CNC tool material selection depends on work material hardness, strength, and properties, as well as machining requirements and cutting parameters. Choosing suitable materials can improve machining quality, efficiency, and tool life, while reducing machining cost and tool wear. Proper CNC tool material selection is thus critical.

- Coatings: Forming a coating on the tool using chemical vapor deposition, physical vapor deposition, etc. Common coatings are titanium nitride, tungsten carbide, aluminum nitride.

- Nitriding: Heating tools to high temperatures and nitriding in ammonia or nitrogen atmosphere to form a hard nitrided layer improving wear resistance.

- Anodizing: Suitable for aluminum alloys, anodic oxidation forms an oxide layer increasing surface hardness and corrosion resistance.

- Passivation: Chemically treating tool surfaces to form a protective oxide film improving corrosion resistance.

- Heat treatment: Heating tools to specific temperatures followed by rapid cooling to enhance hardness and wear resistance.

These treatments offer advantages like:

- Improved wear resistance: Wear-resistant coatings significantly increase tool life.

- Reduced friction: Some coatings reduce friction between tools and workpieces, decreasing heat and wear.

- Preventing adhesion: Coatings prevent chip welding and material adhesion preventing tool damage.

- Higher cutting speeds: Improved lubricity and heat conduction allow higher cutting speeds, improving productivity.

- Corrosion resistance: For working in high temperatures or corrosive environments.

“Which came first – the tool or CNC machining?” relates to manufacturing development and technological advancement. In truth, tools and CNC machining evolved concurrently, promoting and enabling progress.

Before answering, let’s understand the concepts:

- Tool: A device used for cutting, machining, drilling, etc. Tools existed for manual operation long before CNCs, used for working materials. Tool materials, design, and fabrication improved over time to meet demands.

- CNC Machining: Automated machining process where computer numerically controls machine tools and motion. CNC enables high automation and precision by precisely controlling machining parameters. CNC gradually developed after the industrial revolution and is indispensable for modern manufacturing.

In summary, tools and CNC machining co-developed rather than one preceding the other. Early CNC machining leveraged existing tool designs and machining know-how. Well before CNCs, people had a variety of tools improved over time to meet machining needs.

With CNC development, tools evolved to meet demands of high-speed, high-precision CNC machining. This led to innovations like carbide and coated tools for improved performance and productivity.

Thus, tools and CNC machining promoted and enabled each other’s progress. Tools provided the foundation, while CNCs drove tool innovation and enhancement – both advancing manufacturing forward.

Frequently Asked Questions(FAQ)

Q: How do I determine the appropriate cutting speed for my CNC machining process?

A: Refer to the cutting speed charts for specific materials provided by tool manufacturers. These charts consider the material, tooling, and machine capabilities to recommend optimal cutting speed ranges.

A: Coated tools offer benefits like increased tool life, reduced friction, improved surface finish, and enhanced wear resistance. The coating acts as a protective layer, allowing better performance under demanding conditions.

A: Yes, many CNC tools can be reconditioned or regrounded to extend service life. However, manufacturer’s guidelines must be followed and tooling experts consulted to ensure proper restoration protocols.

A: To minimize deflection, ensure proper clamping and stability of tool and workpiece. Also consider reducing cutting forces by adjusting parameters, using shorter tools, or selecting higher rigidity tools.

Q: What factors should I consider for tool coatings in CNC machining?

A: For coatings, consider the work material, cutting speed, feed rate, and desired finish. Different coatings provide specific advantages, like wear resistance or reduced friction depending on requirements.

A: Yes, matching the tool holder and spindle interface is important for accurate tool positioning and stability. Mismatch can lead to tool runout, workpiece damage, and poor accuracy, so proper interface match is critical.

Choosing suitable CNC machining tools is vital for efficient, accurate machining. This guide covered key considerations, tool types, and tips for selecting CNC tools. By comprehensively assessing factors like material compatibility, operations, tool geometry, speeds, coatings, etc. You can make informed decisions and ensure machining success. For more information, please contact us.