Challenge time: February 2023

Challenge location: Longhua, Shenzhen, China

Customer information: Singaporean high-quality mold vendors

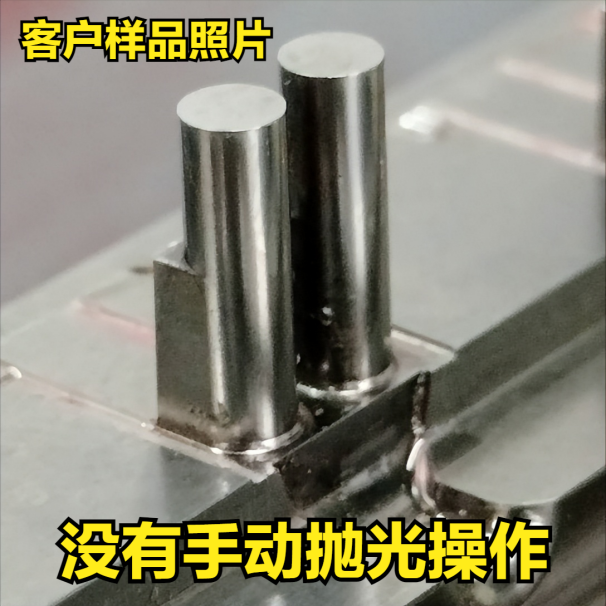

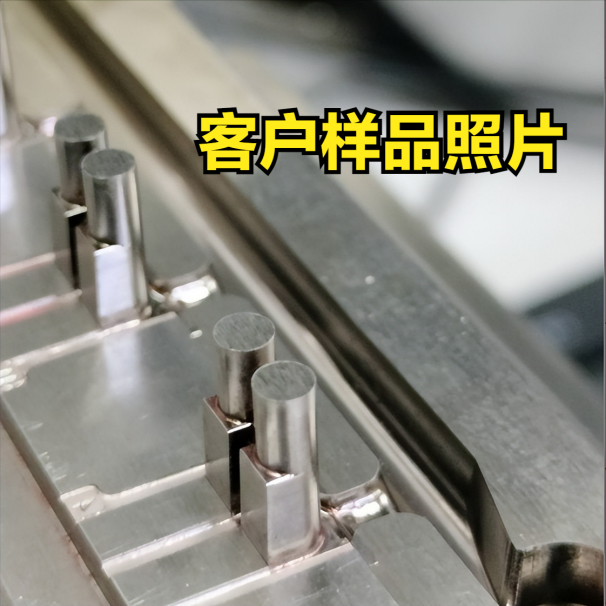

No nonsense, first upload the customer photo:

Customer physical photos (1)

Customer physical photos (2)

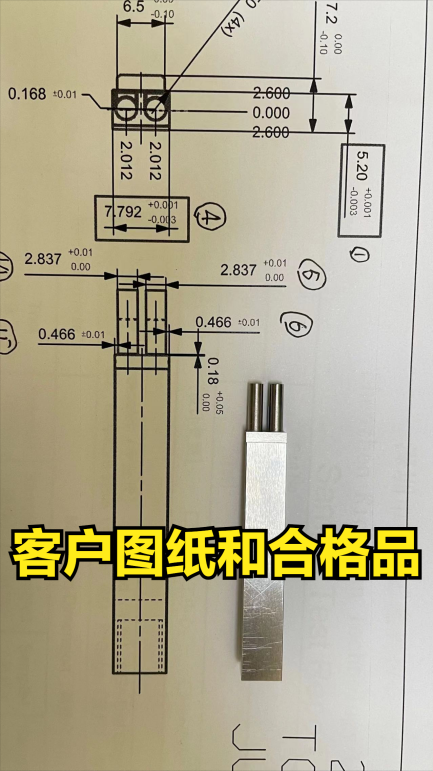

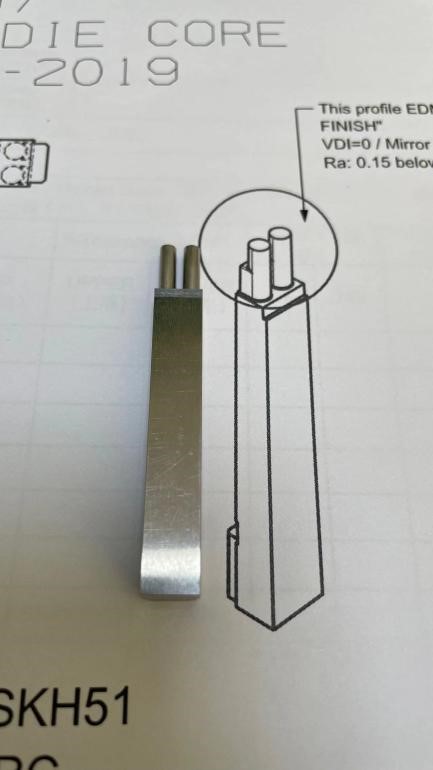

Firstly, MIRROR-EDM mold components are high-precision parts that require extremely high surface accuracy and smoothness. When a customer requests us to manufacture MIRROR-EDM mold components with H2 grade machining accuracy, we need to take a series of measures to ensure machining accuracy and quality.

Of course, this process was also quite tortuous. When we first used SODISCK’s slow wire-cutting and W-EDM machines for machining, the resulting product completely failed to meet the customer’s requirements, as shown on the left side of the following figure (NG part).

The left side shows the non-conforming part, for comparison and judgment.

After the customer complained about the NG parts, we determined that the accuracy of this component exceeded the requirements for most mold components in China. We needed to modify our process to manufacture parts that met the customer’s requirements. The mirror surface roughness required by the customer could not be achieved through manual polishing and required a precision of H2 (0.001mm). We needed to use higher precision EDM equipment to achieve this level of accuracy.

The process arrangement is as follows:

- Rough machining: Sodick wire cutting machine.

- Mirror EDM: Makino W-EDM.

- Inspection equipment: PC-Dmis with a detection accuracy up to 0.001mm. Domestic Hexagon inspection equipment can only meet an accuracy of up to 0.005mm.

Physical photos (1) Physical photos (2) Physical photos (3)

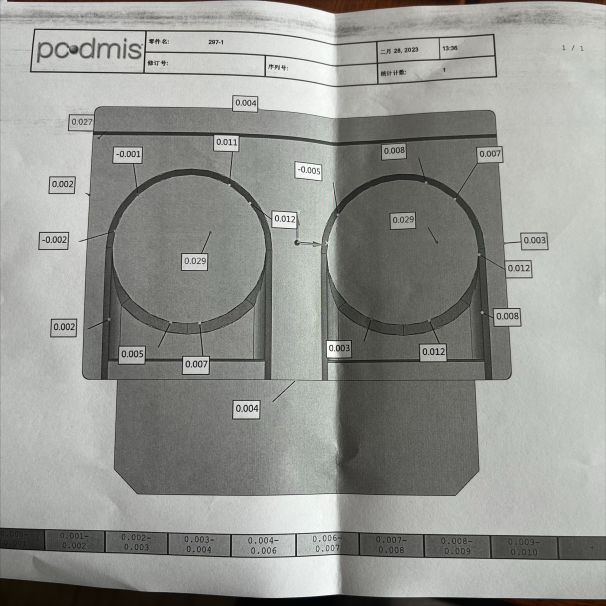

Finally, here is the inspection report generated using a coordinate measuring machine (CMM)。

PC DMSI Inspection report

To achieve high-precision machining of parts, the following processes need to be followed:

Firstly, suitable machining processes and equipment must be selected based on actual requirements. The precision of the equipment is limited by objective factors such as its age and maintenance status. Typically, electrical discharge machining (EDM) equipment requires a high-precision control system that can accurately control the distance and position between the electrode and work-piece, as well as the intensity and frequency of the discharge. We choose the most advanced EDM equipment, such as CNC EDM centers and high-precision wire-cutting machines, to meet customer requirements.

Secondly, the work-piece needs to be pre-processed and rough-machined before precision EDM. Precision machining cannot be completed at high speeds, so the work-piece is milled, turned, ground, and polished to make its surface smoother and flatter. This reduces the time required for EDM and minimizes its impact on the surface, improving processing efficiency, precision, and quality.

In addition to equipment and process requirements, experienced engineers and operators are necessary. They must be able to select appropriate machining parameters and processes, adjust equipment settings and parameters, and identify and solve problems during the machining process to ensure the quality and precision of the final product.

Finally, strict quality control measures are implemented throughout the machining process. Different testing equipment, such as coordinate measuring machines and optical projectors with varying degrees of precision, are used to check the accuracy and quality of the work-piece according to different product requirements. If any problems are found, corrective measures are immediately taken.

In summary, meeting the H2 precision level for mirror EDM mold parts requires a series of measures to ensure processing precision and quality. We use the most advanced equipment and processes, as well as experienced engineers and operators, to meet customer requirements and ensure that the final product quality and precision meet customer expectations.